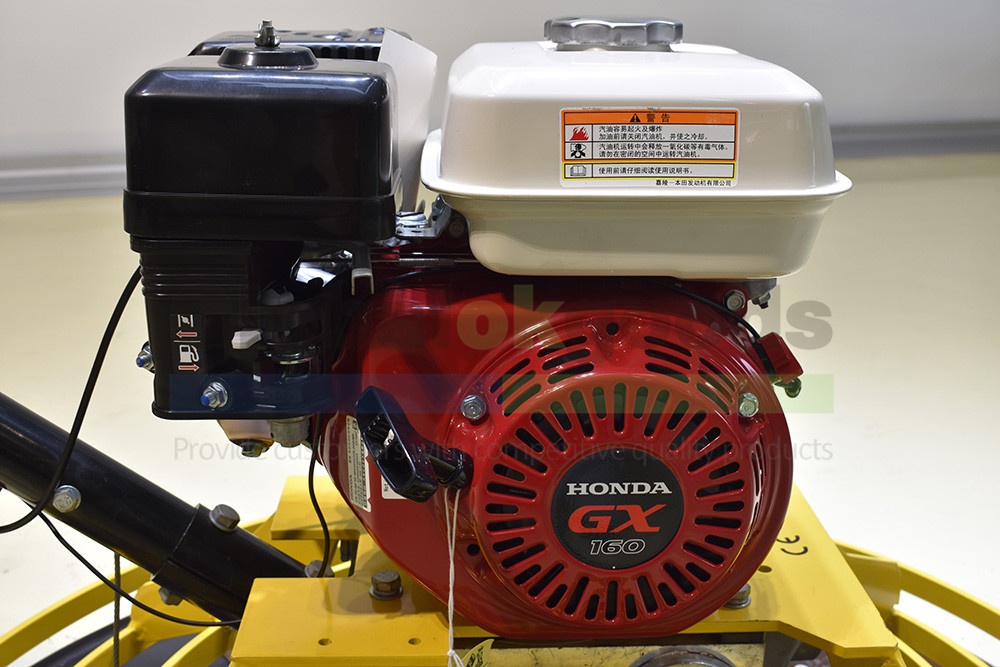

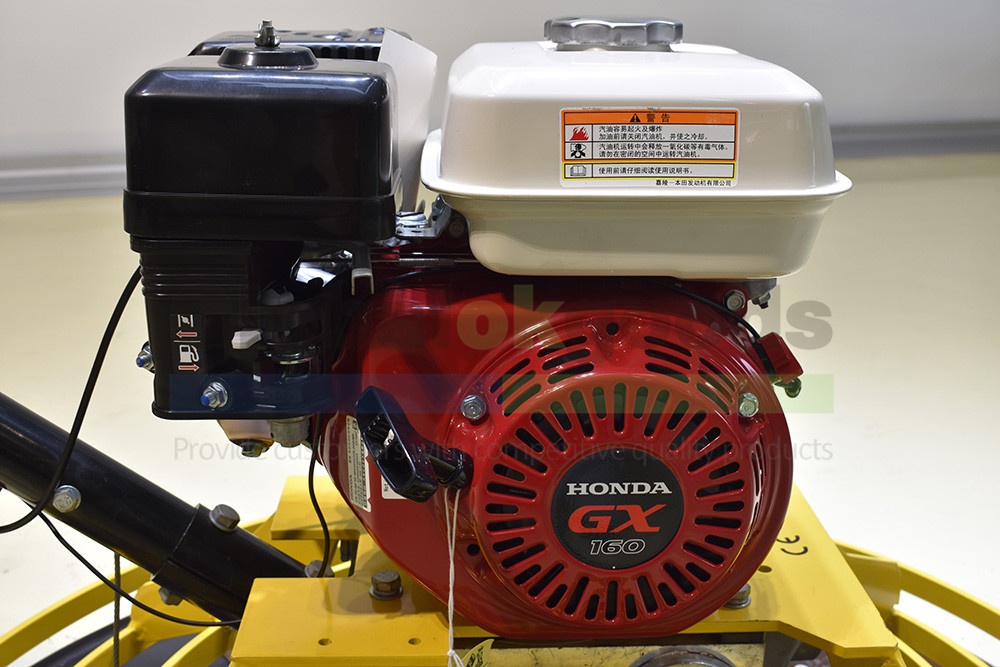

Power trowel is a construction machine used to impart a smooth surface finish on freshly poured concrete slabs. This machine consists of one rotor which rotate parallel with the slab surface.

Discs or multi-bladed attachments are spun against the still soft concrete surface by the rotors, thereby effectively smoothing out any blemishes or high spots.

Technical Data

Technical Data

Power trowel Periodic Maintenance Schedule

Discs or multi-bladed attachments are spun against the still soft concrete surface by the rotors, thereby effectively smoothing out any blemishes or high spots.

Technical Data

Technical Data

| Model | WH-S100H | WH-S100R | WH-S100L | WH-S100S |

| Engine | Honda GX160 | Robin EY20 | Loncin G200F | B&S1062 |

| Engine type | Air-cooled single cylinder 4-stroke | |||

| Power (HP) | 5.5 | 5.0 | 6.5 | 5.0 |

| Trowel diameter (cm) | 92 | |||

| Speed range (r/min) | 60-100 | |||

| Pitch range | 0-15° | |||

| Operating weight (kg) | 96 | 96 | 96 | 96 |

| Shipping weight (kg) | 106 | 106 | 106 | 106 |

| Shipping size (cm) | 100*100*36 | |||

| Engine Periodic Maintenance Schedule | ||||||

| Performed at every indicated month or operation hours interval, whichever comes first. | REGULAR SERVICE PERIOD | |||||

| Item | Directive | Each use | First month or 20 Hrs. | Every 3 months or 50 Hrs. | Every 6 months or 100 Hrs. | Every year or 300 Hrs. |

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √* | |||||

| Sediment cup | Clean | √ | ||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel rank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

| * Replace the paper element type only. | ||||||

| (1) Service more frequently when used in dusty areas. | ||||||

| (2) These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures. | ||||||

| Directive | Daily before starting | After first 5 Hrs. | After first 50 Hrs. | Every week or 25 Hrs. | Every month or 100 Hrs. | Every 3 months or 300 Hrs. |

| Check oil level of machine | √ | |||||

| Check fuel level line and fittings for cracks or leaks | √ | |||||

| Check and tighten engine clylinder screws | √ | √ | ||||

| Check and tighten external hardware | √ | √ | ||||

| Check V-belt | √ | |||||

| Clean engine cooling fins | √ | |||||

| Clean recoil starter | √ | |||||

| Change gearbox oil | √ | √ | ||||

| Clean engine muffler and exhaust port | √ | |||||

| Note: If engine performance is poor, please check, clean and replace air filter elements as needed. | ||||||

USD

USD EUR

EUR GBP

GBP CNY

CNY